The Relevance of Thermal Stability in Heat Transfer Fluid Option

The Role of Warm Transfer Fluid in Enhancing System Efficiency and Security

In the ever-evolving landscape of industrial procedures, heat transfer liquids (HTFs) become crucial parts in enhancing both system efficiency and security. These specialized fluids, understood for their superior thermal conductivity and controlled thickness, make it possible for effective warmth exchange, which is important for structured operations. Nevertheless, the influence of HTFs expands beyond mere efficiency; their intrinsic thermal security and low flammability dramatically add to risk reduction. As sectors come to grips with the requirement for high-performance and secure procedures, recognizing the nuanced role of HTFs becomes critical. What specifically makes HTFs so essential in today's industrial frameworks?

Understanding Warmth Transfer Fluids

Heat transfer liquids, frequently taken into consideration the lifeblood of thermal monitoring systems, play a critical duty in controling temperature throughout numerous industrial applications - heat transfer fluid. Industries such as chemical handling, power generation, and manufacturing count on warm transfer liquids to guarantee tools operates effectively and safely.

The selection of a proper warmth transfer fluid is essential to the success of a thermal administration system. Understanding the nature and feature of these liquids includes identifying their capability to take in, transportation, and release warm power efficiently. Warm transfer liquids can be broadly categorized into various kinds, consisting of water-based, glycol-based, and synthetic oils, each with its particular applications and benefits. The choice of fluid depends upon variables such as temperature variety, thermal security, and compatibility with system products. In recap, a comprehensive understanding of warm transfer liquids is essential for optimizing system performance, guaranteeing operational security, and attaining cost-effective thermal management solutions.

Trick Properties of HTFs

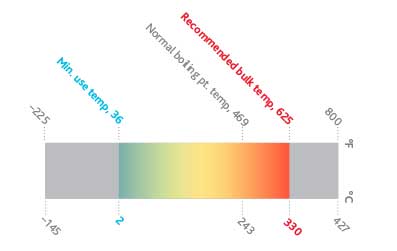

The certain warmth capacity of an HTF defines the quantity of warmth energy required to alter its temperature level, influencing how effectively the system can respond to temperature level variants. The boiling and freezing factors of HTFs additionally play a crucial role, especially in systems subjected to extreme temperatures, making certain liquid security and protecting against stage adjustments throughout procedure.

Enhancing System Efficiency

To boost system efficiency with warmth transfer fluids (HTFs), it is important to integrate a detailed technique that takes into consideration both liquid buildings and system design. The selection of a suitable HTF is essential, as its thermal conductivity, viscosity, and certain warmth capability directly impact the effectiveness of heat exchange. High thermal conductivity guarantees rapid warmth transfer, while optimum thickness promotes smooth circulation via the system, lessening power intake. In addition, a high certain heat capacity allows the fluid to store and move even more thermal energy, enhancing overall system efficiency.

Equally essential is the style of the warmth transfer system itself. The surface location and product of warmth exchangers should be optimized to take full advantage of warmth transfer performance.

Boosting Operational Safety And Security

Ensuring operational safety in heat transfer systems requires a meticulous focus on both the homes of warm transfer liquids (HTFs) and the style and upkeep of the whole system. HTFs need to have thermal security, low flammability, and proper thickness to lessen dangers such as leaks, fires, and system malfunctions. Choosing the best HTF is important as it figures out the system's capacity to manage temperature level variations without compromising safety.

The style of the this post system must integrate redundancies and fail-safes to handle possible dangers effectively. This includes the combination of safety and security valves, stress relief tools, and temperature monitoring systems to spot and deal with anomalies without delay. Normal upkeep is critical to make certain that all parts, consisting of pumps, pipes, and seals, are functioning appropriately and are cost-free from wear or deterioration, which might lead to dangerous leakages or failings.

Moreover, workers in charge of the procedure and maintenance of heat transfer systems have to be effectively trained in safety and security procedures and emergency feedback treatments. Constant training programs and safety drills can substantially reduce the chance of mishaps, ensuring a much safer working environment. Eventually, a comprehensive technique to safety-- incorporating fluid option, system design, and labor force training-- is vital for optimal functional security.

Sector Applications of HTFs

Commonly made use of across numerous sectors, warm transfer liquids (HTFs) play an essential role in improving the performance and dependability of thermal administration systems. In the chemical market, HTFs are important for keeping precise temperatures throughout responses, ensuring product consistency and high quality. They assist in warmth exchange processes in activators, condensers, and heat exchangers, therefore optimizing power use and reducing waste.

In the oil and gas field, HTFs are used in both upstream and downstream procedures. They handle temperature level in boring operations and improve effectiveness in refining procedures by providing stable thermal conditions. This results in reduced downtime and enhanced safety, particularly in important procedures such as purification and splitting.

The sustainable energy industry likewise benefits significantly from HTFs, particularly in focused solar energy (CSP) plants. Below, HTFs move caught solar energy to power turbines, enabling reliable power generation. The pharmaceutical sector depends on HTFs for accurate temperature control in both synthesis and storage space, making certain item effectiveness and safety.

Additionally, the food and drink market utilizes HTFs for pasteurization, sanitation, and cooking processes, boosting both product safety and security and manufacturing efficiency. Throughout these markets, HTFs work as vital components in keeping ideal functional performance and safety.

Final Thought

Heat transfer liquids are vital in improving commercial system performance and safety and security by using high thermal conductivity, optimal viscosity, and thermal stability. Correct choice and upkeep click here to read of HTFs enhance warm exchange efficiency, consequently boosting functional performance. The low flammability of her latest blog these liquids is essential for decreasing risks and making sure safe operations. Comprehensive employees training and regular maintenance additionally support the dependability and performance of commercial processes, solidifying the essential role of HTFs in diverse applications.